Konvergierte deterministische Industrienetze in heterogenen Umgebungen mit Campus-5G (KOSINU5)

| Partner | Siemens Aktiengesellschaft (Nürnberg, Germany) Contact: Franz-Josef Götz Infosim GmbH & Co. KG (Würzburg, Germany) Contact: Dr. David Hock |

| Funder | R&D program "Information and Communication Technology" of the State of Bavaria, Germany |

| Funded period | October 2021 - September 2024 |

| Researcher | Prof. Dr. Tobias Hoßfeld Dr. Florian Metzger Alexej Grigorjew M.Sc. Viktoria Vomhoff M.Sc. |

Project Description

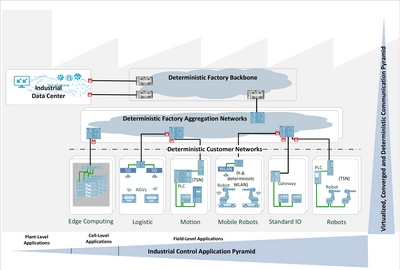

Industry 4.0 is revolutionizing the way companies manufacture, improve and operate their products. Production chains are planned more flexibly, robots are used and machines are networked. These have to communicate with each other. The aim of this project is to develop robust, scalable industrial networks for the intelligent factory and to evaluate their performance. Real-time requirements are placed on the industrial network and guarantees are required for the communication networks of the factory of the future. A particular focus is on the influence of 5G and the air interface with regard to real-time guarantees and the stochastic scalability of 5G for industrial networks. Today's separate subnets for Industry 4.0 applications are being converted into a convergent network infrastructure consisting of heterogeneous, deterministic subnets. These are used jointly by many time-critical (e.g. control, real-time image processing) and non-time-critical applications (e.g. configuration, monitoring) so that the network infrastructure in factories ensures IT / OT convergence. For this purpose, network monitoring mechanisms for selected industrial applications (with regard to performance and resilience for diagnosis or as an early warning system) are to be developed and implemented in the project. Furthermore, interfaces, in particular application-neutral interfaces to the network with the support of various network technologies (5G, WLAN, TSN) and mechanisms for automatic regulation and control of the networks are to be provided. This plug-and-play approach for industrial networks is demonstrated in a proof-of-concept.

Project Objectives

Guarantees for real-time capability in industrial networks

- Validation of the latest IEEE and IETF standards on the data plane and control plane

- Implementation of scalable determinism and scalable Quality of Service (QoS) through a modern data plane

- Evaluation and further development of methods for reliability, e.g. Frame Replication and Elimination for Reliability (FRER)

Real-time capability and determinism in radio networks

- Analysis of the possible interferences with different channel access mechanisms

- Framework for the analytical description of the deterministic and stochastic real-time properties of WLAN and 5G, taking into account various channel access mechanisms

- Definition of a uniform, deterministic IP protocol stack across 5G and other wireless technologies

Heterogeneity of communication networks

- Framework for determining the possibilities and limitations of real-time properties in heterogeneous networks

- Dynamic selection of the most suitable interface for network optimization for devices that offer multiple network interfaces based on different access technologies

- Mechanisms on higher protocol layers (network layer to application layer) that connect the heterogeneous islands, intercept malfunctions and possibly even improve the stochastic real-time properties despite the lack of support from the network access layer in network sections

Need for uniform interfaces for a converged network management of real-time capability

- ML-based autonomous configuration of a deterministic network

- Management system for the heterogeneous device landscape

- Multi-stage early warning system for diagnosis and problem detection

- Evaluation of the mutual influences of different traffic priority levels in the heterogeneous environment

- Active probing and network planning taking into account resilience

Growing demand for “Plug&Play” solutions in industrial networks

- “Plug&Play” option for devices from the entire factory

- Possibility to provide information about the status and condition of each device

- Possibility of automatic reconfiguration of the network